A4 A3 DTF Printer for Epson XP600 8.5/13inch impresora dtf Machine with DTF Oven Direct to Film DTF Printer for Clothes Tshirt

$3,662.40 – $8,424.00

Description

- Hign-concerned Chemical: None

- Application: For Commercial

- After-sale Service: National Joint Guarantees

- Size: 520*400*150mm

- Voltage: 100-240V

- Consumable Type: Black Powder One

- Max. Resolution: 2880*1440dpi

- Color Print Speed: A4 1440*720dpi 3 minutes

- Black Print Speed: A4 1440*720dpi 3 minutes

- Use: DTF printer for clothes

- Signal Connection Type: None

- Print Speed: 20ppm

- Double-sided Printing: No

- Supports Network Printing: Wired

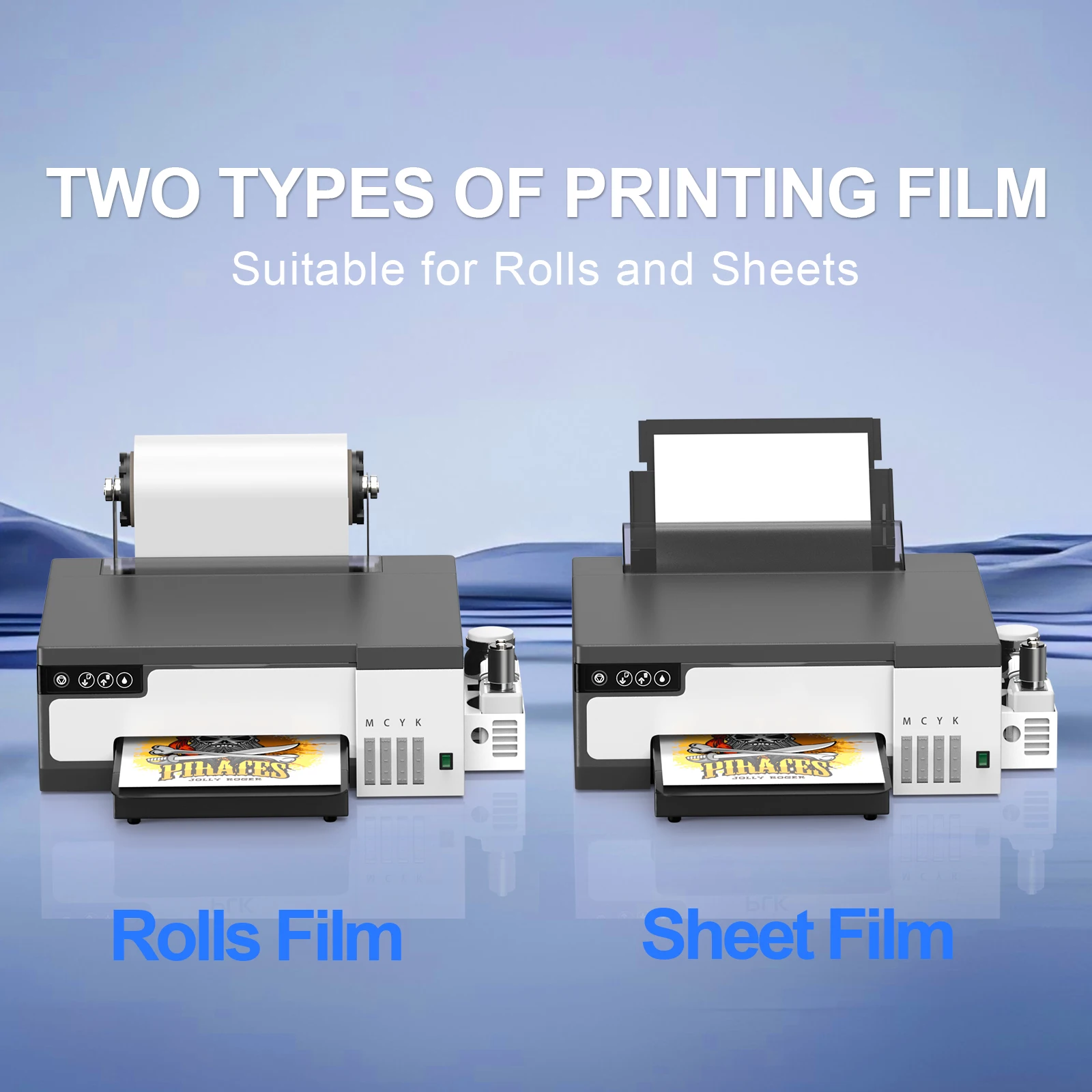

- Paper Feed Mode: Roll Feed

- Max Paper Size: A3+

- Type: Inkjet Printer

- Interface Type: USB

- Brand Name: GMXZE

- Origin: Mainland China

- Certification: CE,RoHS,KC,weee

- Type: A4 DTF printer

- Color: CMYKWW

- Paper: PET film

- Ink: DTF Ink

- Application: T-shirt ,Textile,All kind of fabric

- Function: Direct Transfer Film

- Print head: Epson XP600

- Feature: White ink stirring

- Print software: RIP Ver11

- Maximum printing width: A4 21CM 8.5Inch /A3 33CM 13inch

- ink type and configuration: Y K M C W W

- Printer weight: A4 16KG/ A3 20KG

- Working Power supply: 220V/110V 50HZ/60HZ

A4 A3 DTF Printer for Epson XP600 8.5/13inch impresora dtf Machine with DTF Oven Direct to Film DTF Printer for Clothes Tshirt

DTF (Direct-to-Film) printer is a specialized device used to print designs onto a transfer film, which is then heat-pressed onto fabrics or other materials. This method has gained popularity for its versatility, durability, and suitability for small-batch production

Advantages of DTF Printing :

Material Versatility: Works on cotton, polyester, blends, leather, and even non-textiles (wood, metal).

No Pretreatment: Unlike DTG (Direct-to-Garment), fabrics don’t require pre-coating.

Vibrant Colors: White ink allows bright designs on dark fabrics.

Durability: Resistant to cracking and washing.

Cost-Effective for Small Runs: No screens or minimum orders (ideal for custom jobs).

Why Choice Our A4 A3 XP600 DTF Printer?

1. Can print roll film and single pages.

2. Upgrade XP600 nozzle to double the printing speed.

3. White ink stirring system to prevent ink precipitation.

4. You can clean and check the printing nozzles at any time, and then continue printing. There is no need to remove the film inside the machine when cleaning the printer;

5. The film will not slip during printing, the thickness of the PET film is not limited, and whether it is matte on both sides;

6. Technical support: one-on-one professional after-sales guidance, no need to worry about any printer operation issues.

Printer Parameter :

Product Model: L8058/L18058 DTF Printer

Colors:CMYKWW

Printing speed:A4 1440*1440dpi ,5 Minutes

Software: RIP Ver 11

Print head: For EPSON XP600

Maximum printing width:A4/ 21CM / A3 33CM

Ink consumption: 1 square meters / 20ml

How to Use DTF Printer ?

1. Design Preparation: Create or upload a digital design (with a white underbase for dark fabrics).

2. Printing: The design is printed onto a PET film.

3. Powder Application: Adhesive powder is evenly sprinkled over the wet ink.

4. Curing: The film is heated (100–160°C) to melt the powder and dry the ink.

5. Transfer: The film is placed on the fabric and heat-pressed (130–160°C for 10–15 seconds).

Key Components of DTF Printing :

DTF Printer:

Uses pigment-based inks (typically CMYK + white) to print onto a PET film.

Modified inkjet printers (e.g., Epson, Ricoh) or dedicated DTF printers (e.g., ColDesi, DTF Super).

Adhesive Powder:

A thermoplastic powder applied to the printed film before curing. It ensures the design adheres to the fabric.

Curing Oven or Heat Press:

Melts the adhesive powder and bonds the design to the fabric.

Reviews

There are no reviews yet.